Equipment Guide > Mechanical Testing

Mechanical testing equipment to determine the mechanical properties of materials.

Understanding materials mechanical properties is essential when designing components. Mechanical testing enables quantifiable measurement of a materials performance; this is essential for research and development of new materials, and understanding how modifications made to materials affect performance.

Equipment

- Universal Mechanical Testers – 20 kilonewtons & 50 kilonewtons

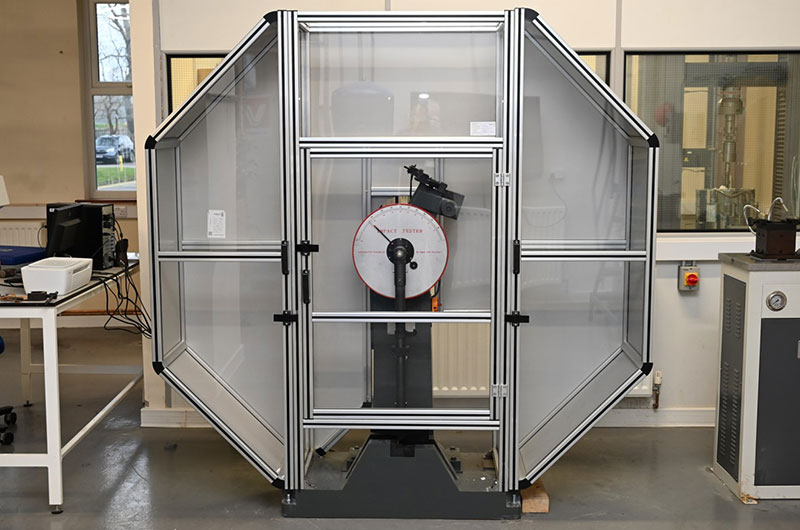

- Charpy Impact Tester – 250 Joules

Applications and Capability

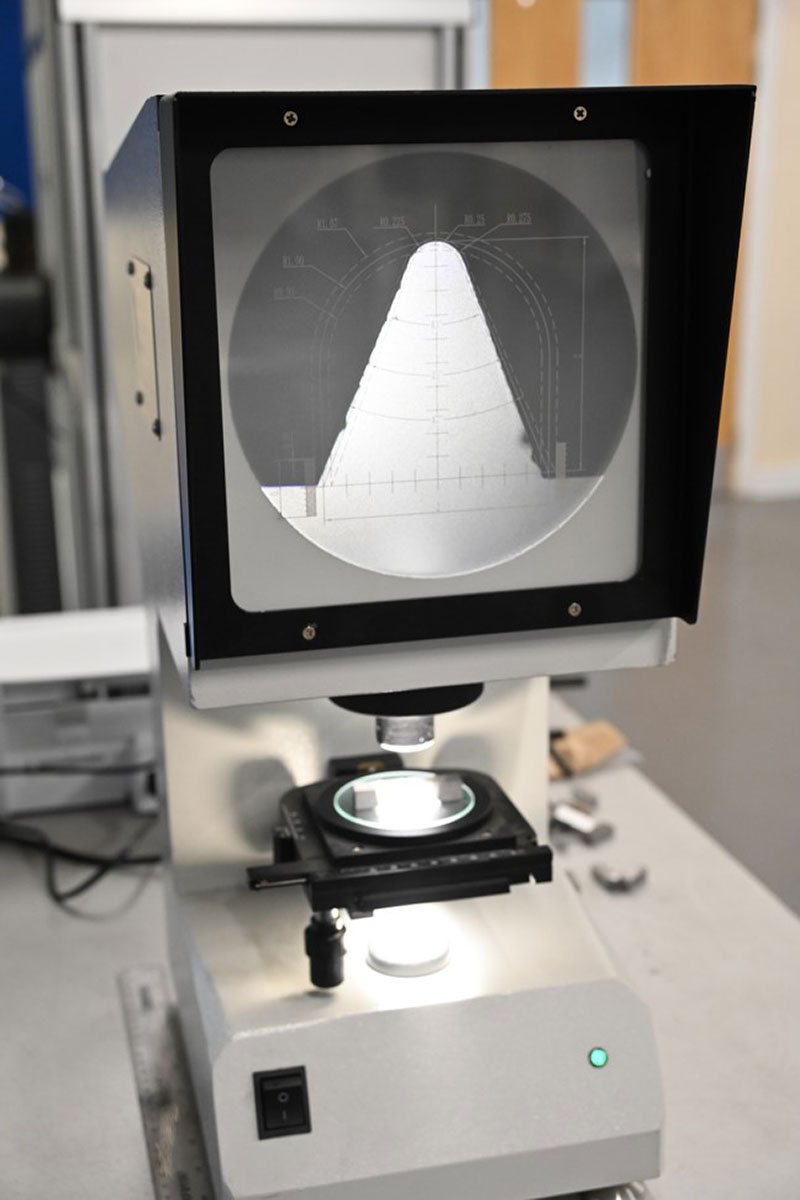

Universal Mechanical Testers - Equipment with the capability of performing a range of tests and operating at temperatures up to 1100°C.

Types of testing available:

- Tensile testing - To determine how a material reacts to forces being applied in tension to provide details about strength, elasticity, ductility, stiffness, and toughness. Tensile testing is widely used in material selection, quality control, and research and development:

- Compression testing - To determine how a material behaves under a compressive load, providing details about compressive strength, elasticity, deformation behaviour, stiffness, and stress-strain relationship. Compression testing ensures that materials meet the necessary standards and specifications for safe and efficient performance in real-world applications.

- Impression creep testing - To study the creep behaviour of materials, especially at high temperatures and over long durations. Typically used for deformation measurement, and high temperature testing. Impression creep testing provides assessment of the time-dependent deformation behaviour of materials under stress and temperature, helping with material selection and design.

- Creep testing - To measure the deformation of a material under a constant load or stress over an extended period, typically at elevated temperatures. This test is crucial for components subjected to long-term loading in high-temperature environments. Understanding material creep behaviour helps with understanding material lifespan and optimising designs.

Charpy Impact Tester

- The Charpy Impact Tester is used to evaluate a materials toughness and its ability to absorb energy during fracture. This test is crucial for assessing the impact resistance of materials, particularly where they are exposed to sudden forces or shocks. Applications that the Charpy Impact Test is used for include material selection, quality control, and failure analysis.

Key Features

- Universal Mechanical Testers – Calibrated to UKAS standards

- Charpy Impact Tester – Calibrated to UKAS standards

Analysis

Test results using this equipment allows the properties listed to be determined.

- Ultimate tensile strength

- Tensile yield point

- Modulus of elasticity (Stiffness)

- Ductility

- Elongation

- Reduction of area

- Toughness

- Resilience

- Poissons ratio

- Creep resistance

- Compressive yield stress

- Compressive ultimate stress