{{serverconnectlatestnews.data.showlatestnews.data[0].news_title}}

{{serverconnectlatestnews.data.showlatestnews.data[0].news_date.formatDate("d MMM yyyy")}}

{{serverconnectlatestnews.data.showlatestnews.data[0].news_teaser}}

The Industrial Digitalisation Group supports process improvements through digitalisation of material processes, advanced characterisation strategies and sensor development.

Artificial Intelligence (AI) and native designed productivity tools are used to create materials data space enabling material information to be digitally managed, automatically accessed and reconstructed with respect to their properties, process and life-cycle conditions.

Managing the efficiency of production, manufacturing and operational processes can be vastly improved through digital workflows. Only by consistently describing material properties and subsequent adjustments made to these, can management of product life cycles reach a higher level and yield new business models.

The Industrial Digitalisation Group leverages the unique combination of advanced materials characterisation and development laboratories including pilot scale materials processing to support its development of digital tools and techniques to manage material and process data.

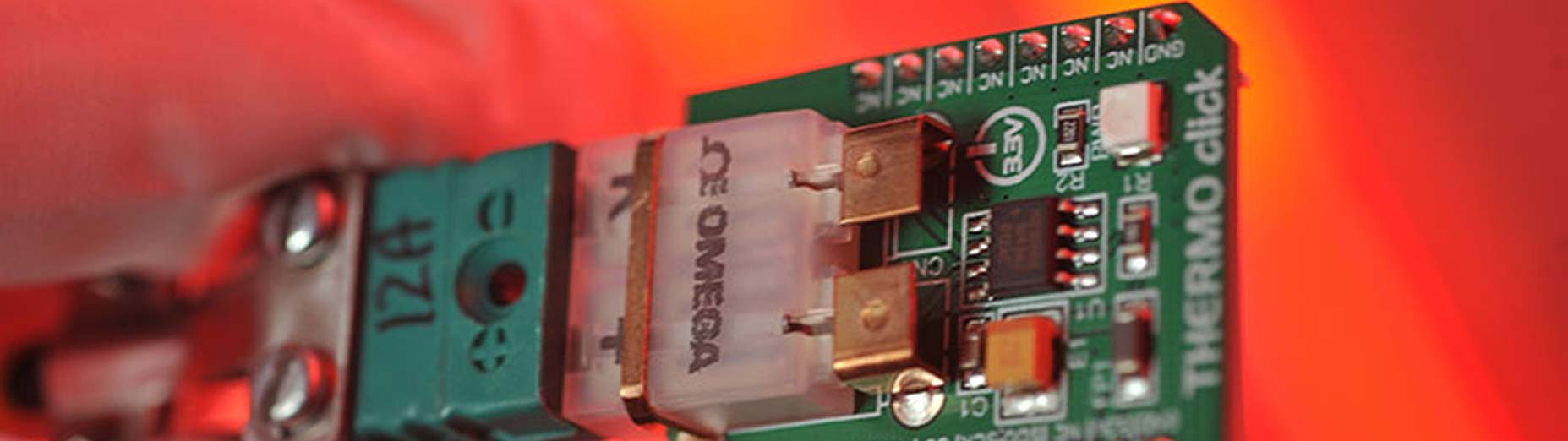

Digital technologies including workflow tools and sensors are developed and built, with focus on new measurement and characterisation techniques. Process, electronic and software engineers work with a broad range of material data and processes, including the latest AI tools to augment knowledge and accelerate the development of materials and processes to meet the more challenging industrial requirements.

The Group can work with a broad range of material data and processes.

Decades of process knowledge and data including pilot scale processing capability to support development of digital tools. An advance Machine Learning and AI laboratory to support materials characterisation and process development to meet faster innovation cycles.

To find out more about the Industrial Digitalisation Group or to make an enquiry, please email enquiries@mpiuk.com