Equipment Guide > Powders and Additive Manufacturing > Particulate Material Characterisation

Particulate material characterisation is the process of analysing and determining the properties and characteristics of particulate materials.

Understanding the properties of particulate materials, supports the optimisation of processes and can improve product performance.

Description

The Institute has a suite of instruments to assess a particulate materials’ properties in relation to storage, transportation and performance in processing such as metal additive manufacturing.

- Automated image analysis system - Identifies morphological and size.

- Automated packing density analyser - Measures bulk and tap density of particulate material.

- Automated avalanche tester - Measures flowing angle, cohesion, and roughness of powders to evaluate their flowability.

- Surface profilometry - analyses surface roughness, texture and morphology of powder bed to validate spreadability and flowability of particulate material.

- Powder storage capacity - provides a proper and precise environmental/atmosphere control.

Predicting Powder Performance

A new characterisation methodology correlating powder physical parameters was developed to represent and predict the powder flowability performance prior to the process.

Key Features

- A fully automated static image analysis system providing a complete, detailed description of the morphological and size properties of particulate materials.

- Delivers precise characterisation of individual particles within pre-dispersed samples of dry powders, wet suspensions, and particulates deposited on filters.

- Statistically representative distributions are constructed by rapidly analysing hundreds of of particles, providing valuable information on the whole sample.

- The system covers particle size range from 0.5 μm up to 1.3mm, sample and substrate dependent (or larger for certain samples).

- Multiple size and shape parameters are calculated for each particle and distributions generated on each parameter.

- Powder behaviour submitted to successive taps is analysed with an automated device and from this, the tapped density parameters are measured precisely (0.4% of accuracy).

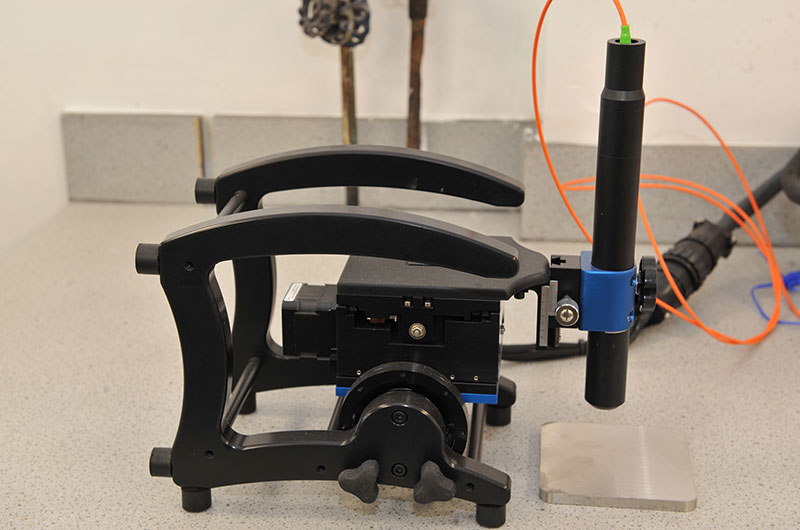

- Powder flowability measurement is based on the rotating drum principle. For each rotating speed, the flowing angle is computed from the average interface position and the dynamic cohesive index is measured from the interface fluctuations.

- Surface optical profilometry measurement is a 3D, non-contact surface analysis using Chromatic Confocal technology to accurately determine physical characteristics of the surface including roughness, morphology, powder spreadability and quality of the powder bed.

Equipment

- Malvern Morphologi 4

- Granutools Automated GranuPack

- Granutools Automated GranuDrum

- Portable Surface Profilometer