Equipment Guide > Scanning Electron Microscopy

Scanning electron microscopy (SEM) is an analysis technique which obtains information about composition and topography of an object by scanning its surface to create a high-resolution image.

SEM uses a focused beam of electrons to do this. The resulting images show information about what the object is made of and its physical features. SEM has a broad range of applications, across several industries and sectors.

- A suite of high resolution Field Emission Scanning Electron Microscopes (FE-SEM) are available

These scanning electron microscopes are complimented with the latest technology, including:

- Wavelength Dispersive Spectroscopy (WDS) and Electron Diffraction Spectroscopy (EDS) detectors offering light element analysis

- Electron Back-scatter Diffraction (EBSD)

- In situ hot stage up to 1400°C

- In-situ tensile stage

- Environmental Scanning Electron Microscopy (ESEM)

Equipment

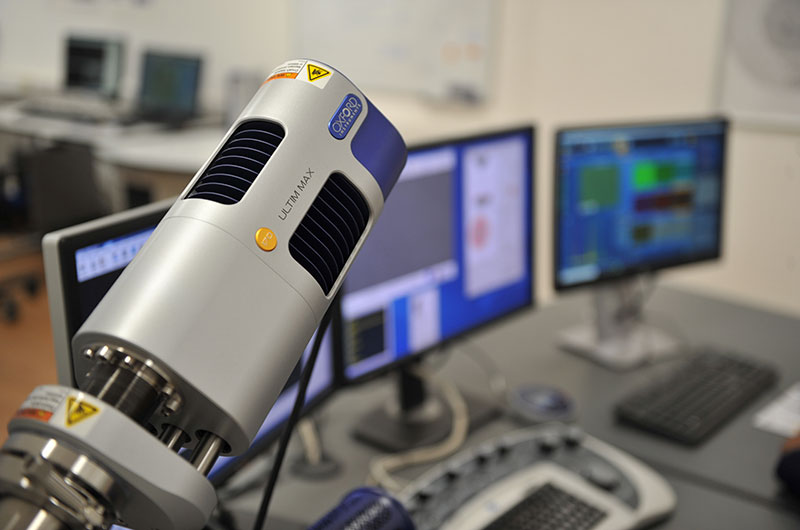

FEI Quanta 650 w/Scanning Electron Microscope

- Oxford Instruments Ultimax 100 EDS detector

- In-situ 1400°C stage

- ESEM Mode

Zeis Sigma 300 w/Scanning Electron Microscope

- Oxford Instruments Symmetry S2 EBSD

- Oxford Instruments AztecWave WDS & Ultimax 170 EDS detector

- In situ tensile stage

Key Features

- Field Emission Gun SEM provides high resolution, high magnification analysis even at low accelerating voltages

- Light element analysis to Li detection using Wavelength Dispersive Microscopy and Electron Diffraction Spectroscopy

- Electron Back-scatter Diffraction analysis

- In situ hot stage

- In situ tensile stage

Applications and Capability

- Microstructural analysis

- Fracture analysis

- Qualitative and semi-qualitative compositional analysis

- In-situ analysis for microstructural transformations at elevated temperature or under strain conditions

- Environmental scanning electron microscopy (ESEM mode) for non-metallic, non-conductive or biological samples

- In-situ elevated temperature analysis (up to 1400°C)

- In-situ tensile testing