{{serverconnectlatestnews.data.showlatestnews.data[0].news_title}}

{{serverconnectlatestnews.data.showlatestnews.data[0].news_date.formatDate("d MMM yyyy")}}

{{serverconnectlatestnews.data.showlatestnews.data[0].news_teaser}}

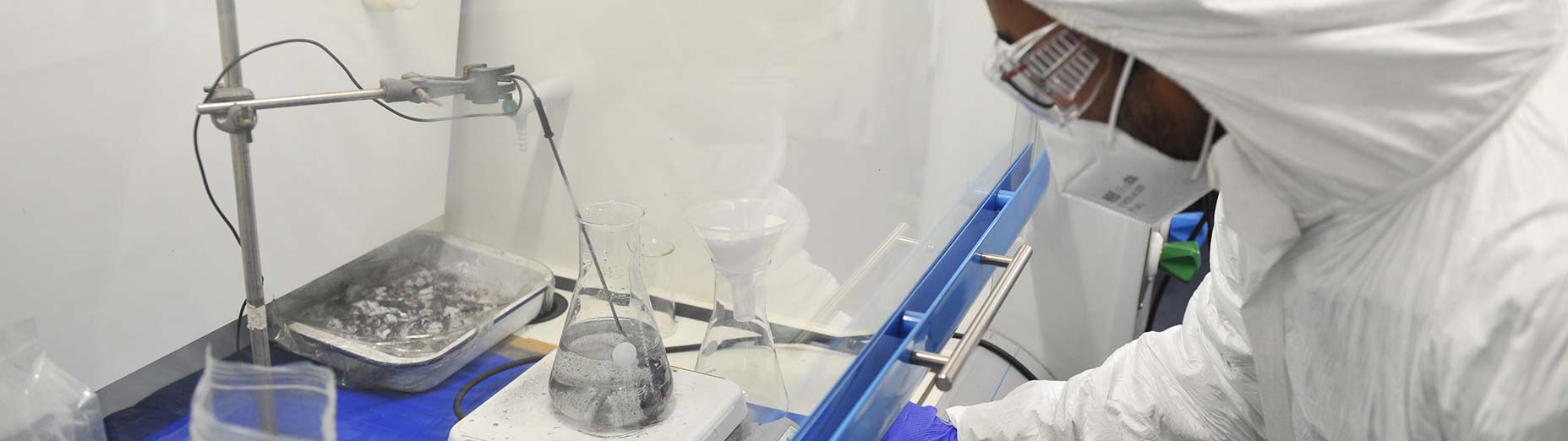

The Critical Raw Materials Group investigates and develops recovery routes for critical raw materials. This includes recovering additional materials from mine tailings through to end-of-life recovery. Work carried out ranges from laboratory research through to pilot scale research to assess opportunities to improve existing processes and develop new technologies for primary and secondary raw materials recovery.

The Group investigates how to recover critical raw materials, with flexibility to switch between different methodologies. This includes using hydrometallurgy and pyrometallurgy processes where proofed concepts can be identified, demonstrated and scaled up. Cross sector support is available with the capability to match pyrometallurgical and hydrometallurgical treatments to suit process flow sheet requirements.

Specialist equipment and facilities enabling hydrometallurgical and pyrometallurgical treatments to support materials recovery along with materials characterisation and analysis.

To find out more about the Critical Raw Materials Group or to make an enquiry, please email enquiries@mpiuk.com