Technology scale-up and de-risking to decarbonise in the cement and concrete industry

Cement production accounts for 7% of global CO₂ emissions making it one of the highest-emitting industries. Reducing CO₂ emissions is therefore crucial to support the sustainability and decarbonisation of the cement and concrete industry.

To enable sustainable production of cement and concrete manufacturers are looking to integrate appropriate decarbonisation strategies, among these are:

- Reducing the amount of clinker in cement

- Reducing the CO₂ from energy used in the production process

- Storing or utilising remaining CO₂ emissions

- Adoption of new methods of cement production

Zero emissions cement

At the Materials Processing Institute, and to support the cement and concrete sectors drive to decarbonise, a key area of research and development focus is sustainable cement and concrete production.

One project where this has been the case and is the Cement 2 Zero project. This project has been looking at the potential to produce zero-emissions cement utilising a new process of clinker production, developed by researchers at the University of Cambridge. The Cement 2 Zero project aims to demonstrate this innovative process on an industrial scale for the first time.

Scaling-up the process

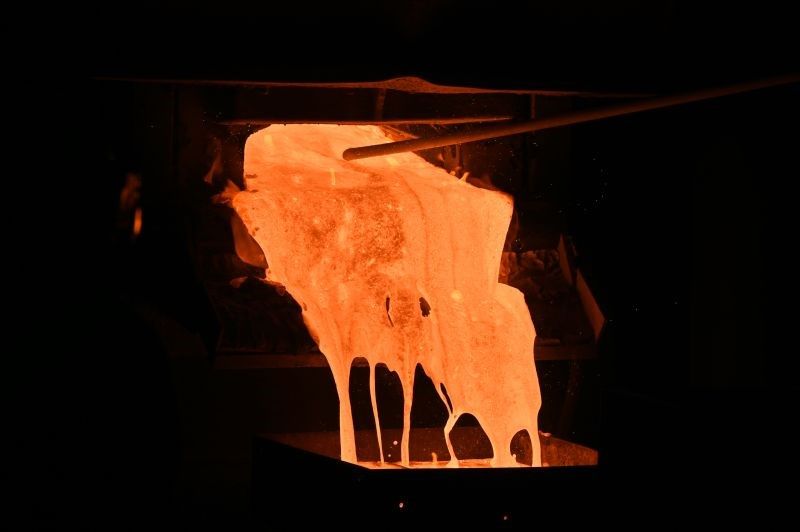

Trials carried out at the Materials Processing Institute have enabled the process to be moved on from laboratory-based research to a much more realistic scale in our 7 tonne Electric Arc Furnace (EAF). These trials have fully investigated the process and were essential to enable the project to move on to the next phase of trials in the full industrial scale EAF at Celsa UK.

Cement Research - Technology Upscaling Trials

Unique research EAF

This is the only operational small tonnage EAF in the UK, which means it is in high demand by clients to research and develop both materials and production processes, as well being available for small scale commercial steel production.

The Cement 2 Zero project has received funding from UKRI as part of the Transforming Foundation Industries Challenge. Cement 2 Zero brings together expertise from the Materials Processing Institute, the University of Cambridge, Celsa UK and supply chain partners, Tarmac, Balfour Beattie, Atkins Realis and Day Aggregates.

Collaborating to achieve industrial decarbonisation

The Cement 2 Zero project is one of several ongoing collaborative research projects involving the Institute and focusing on sustainable cement and concrete. These projects are both grant funded and commercial and involve collaborating with both academic and industrial partners with the aim of supporting the foundation industries to de-risk and scale-up technologies.

Scale-up and de-risking technology

This research utilises equipment at the Institute to enable the scale-up and de-risking of technologies and includes laboratory scale research and testing equipment, induction furnaces ranging from 80kg to 250kg, and the 7 tonne electric arc furnace. Additional capability includes the equipment in our world class Advanced Materials Characterisation Centre where materials analysis is carried out.

Investments to support industry to decarbonise

Our investment programme continues to support the Foundation Industries and other sectors to achieve their sustainability and decarbonisation objectives; this includes a new cement and concrete research facility to be kitted out with a comprehensive range of cement and concrete research and testing equipment, this will expand the research we are able to undertake to continue to drive forward sustainability and decarbonisation in cement and concrete.

Page Link - Cement 2 Zero Project

Video Link - Cement Research - Technology Upscaling Trials

Enquiries email - enquiries@mpiuk.com

26 June 2024