Specialist SEM equipment supports high temperature materials analysis

Analysis of thermal cracking resistance at high temperatures using high specification scanning electron microscopy

REQUIREMENT

As part of a research project, Oxford University needed access to specialist equipment to measure the thermal cracking resistance of a polycrystalline composite material. Thermal cracking resistance is a material's ability to withstand internal stresses caused by rapid temperature changes. To support this research the client was particularly interested in understanding the effect high temperatures would have on the thermal cracking resistance of the material.

SOLUTION

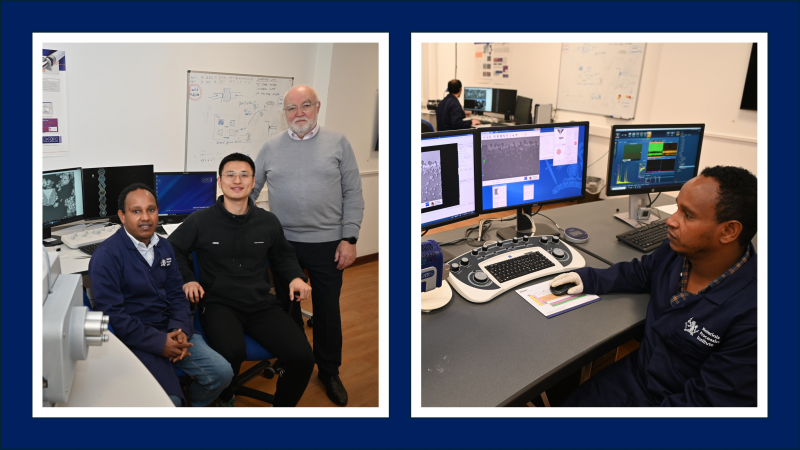

The client submitted several samples of a polycrystalline composite material for analysis. Assessment of the material was carried out using our FEI Field Emission Gun - Scanning Electron Microscope (FEG-SEM), fitted with a hot stage, making it ideal for this type of assessment.

The polycrystalline composite material was heated, using the SEM hot stage, up to 1400°C with incremental temperature increases over time up to given temperature threshold points, in a heating rate range of 10°C-50°C degrees per minute. The thermal cracking resistance (resistance to the formation of microcracking) was observed at x1000 magnification and video recorded.

OUTCOME

The high-resolution images of the polycrystalline composite material as it was heated enabled changes throughout the process to be assessed. Field Emission Gun – Scanning Electron Microscopy provides the very highest resolution imaging compared to regular SEM.

Providing nanometre-level analysis at elevated temperatures can only be achieved on very high specification equipment. The client approached the Institute because we were the only UK facility that they knew of that could provide the equipment capable of the level of assessment that they needed at these temperatures.

17 January 2025